In industria semiconductorum celeriter progrediente, condiciones ambientales accuratas conservare maximi momenti est ad processus fabricationis altae qualitatis.Epitaxia Fasciculi Molecularis (MBE), ars maximi momenti in fabricatione semiconductorum, insigniter utilitatem capit ex progressibus in technologia refrigerationis, praesertim per usum nitrogenii liquidi etfistulae vacuo insulatae (VIP)Hoc blog munus criticum exploratVIPin augendo MBEapplicationes, eius efficaciam et fidelitatem exaggerans.

Momentum Refrigerationis in MBE

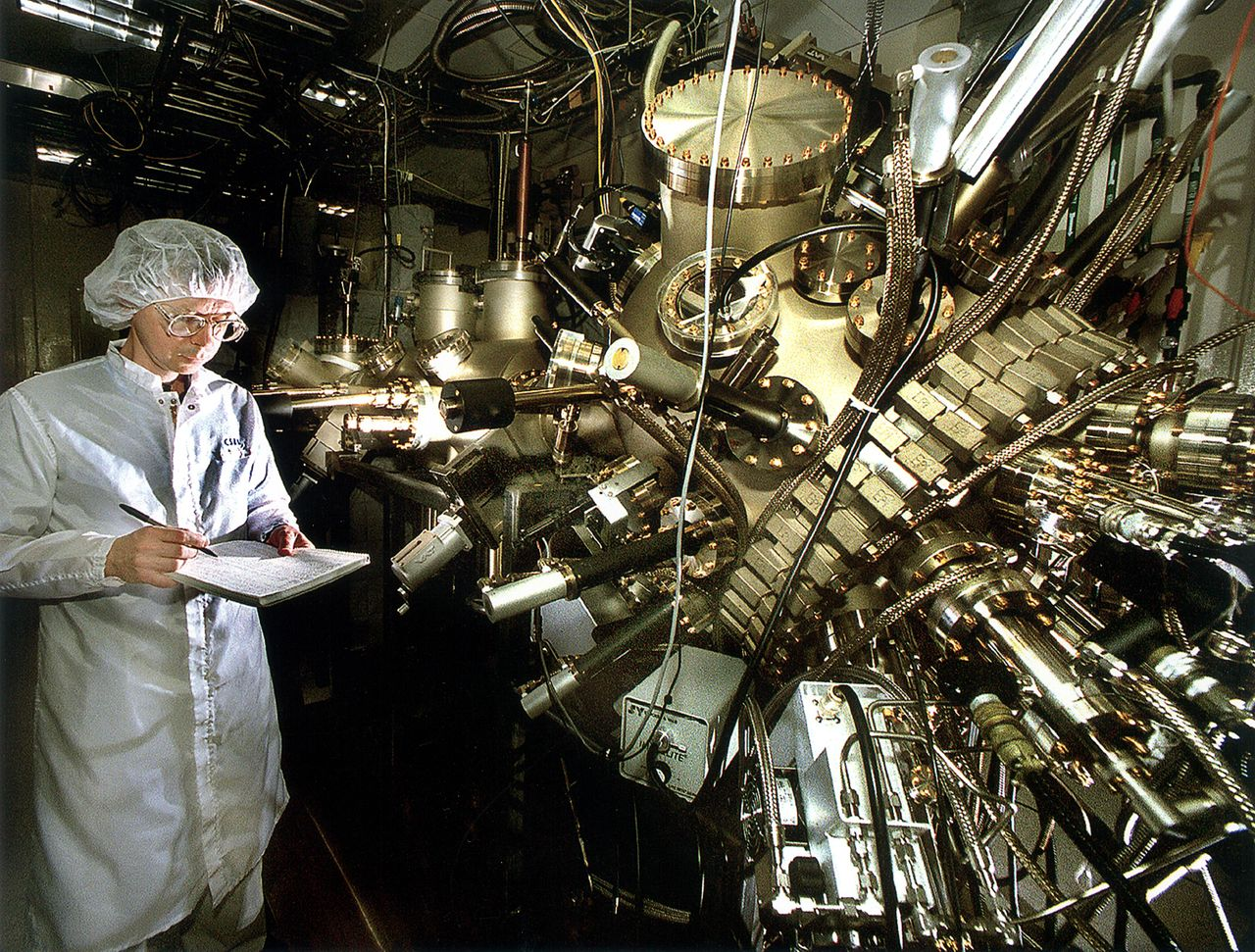

Epitaxia Fasciculi Molecularis (MBE)Methodus valde moderata est deponendi strata atomica in substrato, necessaria ad producenda instrumenta semiconductrix sicut transistores, laseres, et cellulas solares. Ad obtinendam magnam praecisionem requisitam in MBE, temperaturas humiles stabiles servare essentiale est. Nitrogenium liquidum saepe ad hoc adhibetur propter punctum ebullitionis eius humillimum -196°C, quod efficit ut substrata in temperaturis necessariis maneant per processum depositionis.

Munus Nitrogenii Liquidi in MBE

Nitrogenium liquidum in processibus MBE necessarium est, mechanismum refrigerationis constantem praebens qui depositionem sine fluctuationibus thermalibus non desideratis efficit. Haec stabilitas maximi momenti est ad materias semiconductrices altae qualitatis producendas, cum etiam minimae variationes temperaturae ad defectus vel discrepantias in stratis atomicis ducere possint. Usus nitrogenii liquidi adiuvat ad condiciones vacui altissimi quae pro MBE requiruntur assequendas, contaminationem prohibens et puritatem materiarum confirmans.

Commoda Tuborum Insulatorum Vacuo (VIP) in MBE

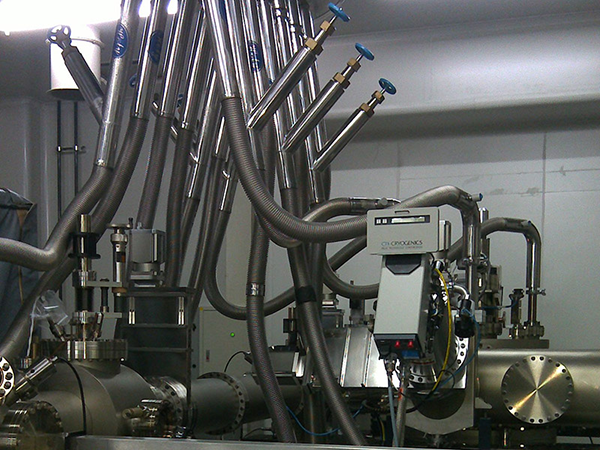

Tubi vacuo insulati (VIP)Perruptionem in efficaci translatione nitrogenii liquidi significant. Hi tubi designantur cum strato vacuo inter duos parietes, translationem caloris significanter minuentes et temperaturam cryogenicam nitrogenii liquidi conservantes dum a repositorio ad systema MBE iter facit. Hoc consilium iacturam nitrogenii liquidi propter evaporationem minuit, suppletionem stabilem et fidam apparatui MBE praebens.

Efficacia et Efficacia Impensarum

UtensVIPinApplicationes MBEplura commoda offert. Amissio caloris imminuta significat minus nitrogenii liquidi requiri, sumptus operationales minuendo et efficientiam augendo. Praeterea, proprietates insulationis...VIPAd ambitum laboris tutiorem conferunt, periculum congelationis aliorumque periculorum cum tractatione materiarum cryogenicarum coniunctorum minuendo.

Stabilitas Processus Aucta

VIPefficit ut nitrogenium liquidum temperatura constanti per totum iter suum adSystema MBEHaec stabilitas maximi momenti est ad condiciones strictas conservandas quae necessariae sunt ad fabricationem semiconductorum altae praecisionis. Per impedimentum fluctuationum temperaturae,VIPAdiuvat ad producendas stratas semiconductorum uniformiores et sine vitiis, qualitatem et efficaciam generalem productorum finalium augens.

HL Instrumenta Cryogenica: Ducens Viam cum Systematibus Circulationis Nitrogenii Liquidi Provectis

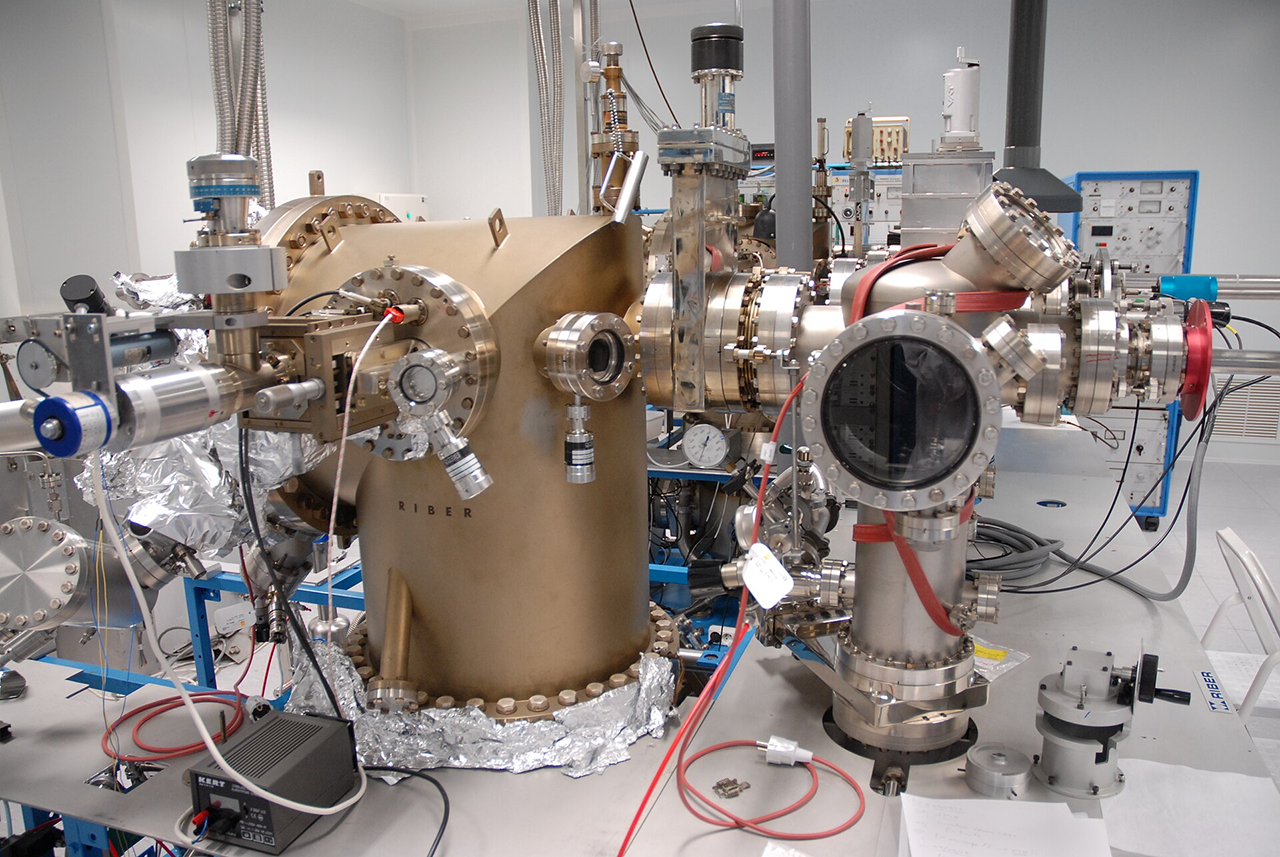

Societas HL Cryogenic Equipment Co., Ltd. modernissimum apparatum elaboravit et investigavit.Systema Circulationis Transportationis Nitrogenii LiquidiQuod a cisterna repositionis incipit et cum apparatu MBE terminatur. Hoc systema functiones translationis nitrogenii liquidi, exonerationis impuritatum, reductionis et regulationis pressionis, exonerationis nitrogenii, et recirculationis efficit. Totus processus sensoriis cryogenicis observatur et a PLC regitur, quod commutationem inter modos operationis automaticum et manualem permittit.

Hoc systema nunc stabile apparatum MBE a fabricatoribus praestantibus, ut DCA, RIBER, et FERMI, operatur. Incorporatio...Instrumenta Cryogenica HL'Systema provectum nitrogenii liquidi fidilem et efficientem copiam praestat, perfunctionem et stabilitatem processuum MBE ulterius augens.

Conclusio

In industria semiconductorum, praesertim in Applicationes MBE, usus nitrogenii liquidi etfistulae vacuo insulatae (VIP)est indispensabilis.VIPNon solum efficientiam et sumptus-efficientiam systematum refrigerationis auget, sed etiam stabilitatem et praecisionem necessariam ad fabricationem semiconductorum altae qualitatis praestat. Cum postulatio instrumentorum semiconductorum provectorum crescit, innovationes in...VIPtechnologia et systemata provecta qualia sunt ea quae abInstrumenta Cryogenica HLMunus criticum aget in requisitis industriae strictis implendis et progressibus futuris impellendis.

Utilitatibus utendoVIPetInstrumenta Cryogenica HL'ssophisticatusSystema Circulationis Transportationis Nitrogenii Liquidi, fabri semiconductorum maiorem constantiam, efficaciam, et salutem in processibus MBE suis consequi possunt, tandem ad evolutionem instrumentorum electronicorum novae generationis conferunt.

Tempus publicationis: Iun-XV-MMXXIV